Description

| ATEX Nylon Cable Gland |

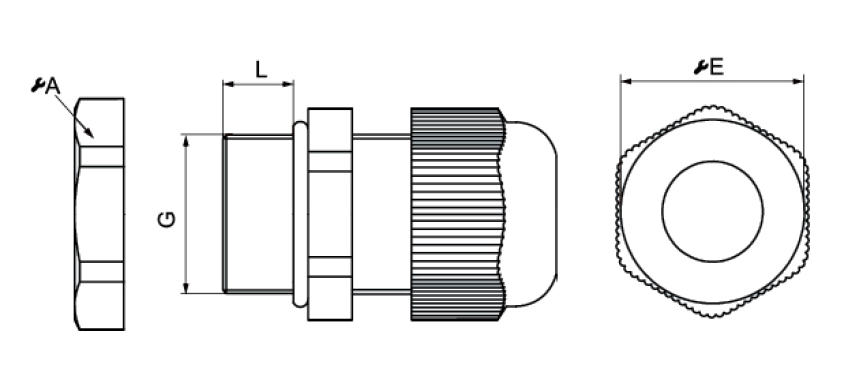

| Code |

Thread Size |

Cable Range |

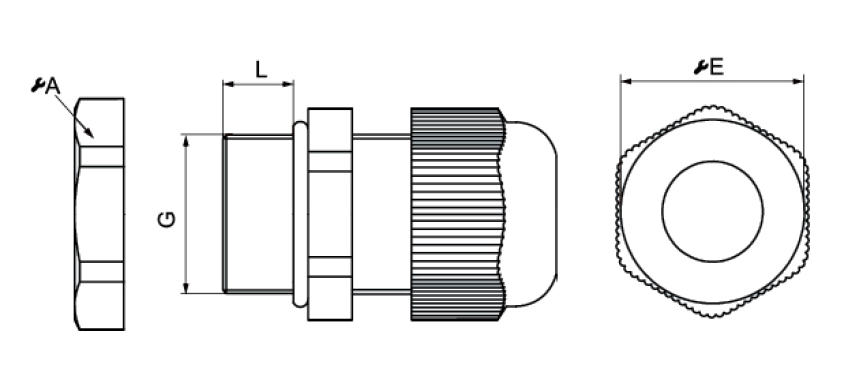

Thread O. D. G |

Thread Length L |

Spanner Size A & E |

Qty/bag |

| Exe-N-PG7 |

PG7 |

4-6.5 |

12.5 |

9 |

19/16 |

100 |

| Exe-N-PG9 |

PG9 |

4.5-8.5 |

15.2 |

9 |

22/19 |

100 |

| Exe-N-PG11 |

PG11 |

5-10 |

18.6 |

9 |

24/22 |

100 |

| Exe-N-PG13.5 |

PG13.5 |

6-11 |

20.4 |

10 |

26/24 |

100 |

| Exe-N-PG16 |

PG16 |

8-13 |

22.5 |

10 |

30/27 |

100 |

| Exe-N-PG21 |

PG21 |

13-18 |

28.3 |

12 |

36/33 |

100 |

| Exe-N-PG29 |

PG29 |

18-25 |

37 |

12 |

46/42 |

50 |

| Exe-N-PG36 |

PG36 |

23-32 |

47 |

15 |

56/52 |

20 |

| Exe-N-PG42 |

PG42 |

30-38 |

54 |

18 |

65/60 |

20 |

| Exe-N-PG48 |

PG48 |

37-44 |

59.3 |

18 |

69/68 |

20 |

|

|

|

|

|

|

|

| Code |

Thread Size |

Cable Range |

Thread O. D. G |

Thread Length L |

Spanner Size A & E |

Qty/bag |

| Exe-N-M12x1.5 |

M12x1.5 |

4-6.5 |

12 |

9 |

17/16 |

100 |

| Exe-N-M16x1.5 |

M16x1.5 |

4.5-8.5 |

16 |

9 |

22/19 |

100 |

| Exe-N-M20x1.5 |

M20x1.5 |

6-11 |

20 |

10 |

27/24 |

100 |

| Exe-N-M25x1.5 |

M25x1.5 |

13-18 |

25 |

12 |

33/33 |

100 |

| Exe-N-M32x1.5 |

M32x1.5 |

16-21 |

32 |

12 |

41/36 |

50 |

| Exe-N-M40x1.5 |

M40x1.5 |

20-27 |

40 |

15 |

51/46 |

20 |

| Exe-N-M50x1.5 |

M50x1.5 |

30-38 |

50 |

18 |

61/60 |

20 |

| Exe-N-M63x1.5 |

M63x1.5 |

37-44 |

63 |

18 |

74/68 |

10 |

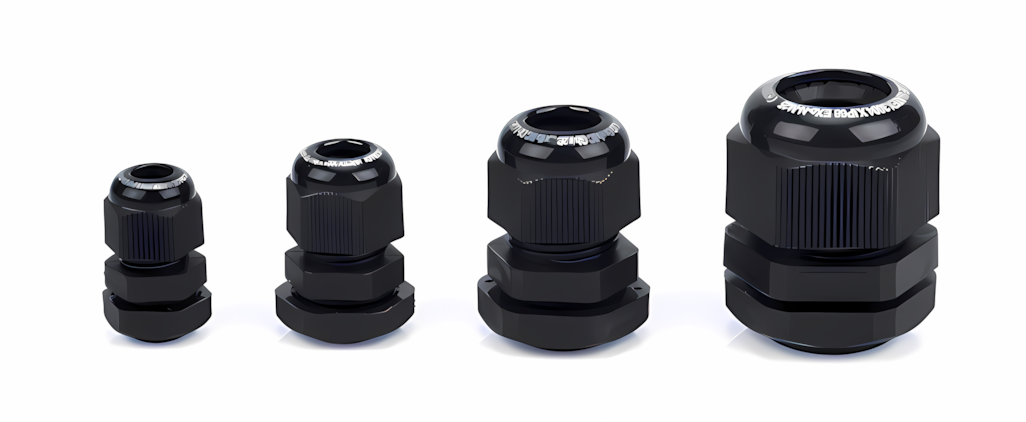

Our rong wei electric ATEX certified explosion – proof cable gland represents the pinnacle of safety and reliability for electrical installations in explosive environments. ATEX (Atmosphères Explosibles) certification, a mark of excellence recognized across Europe and globally, ensures that this cable gland has undergone rigorous testing and meets the strictest safety regulations for areas prone to explosive atmospheres.

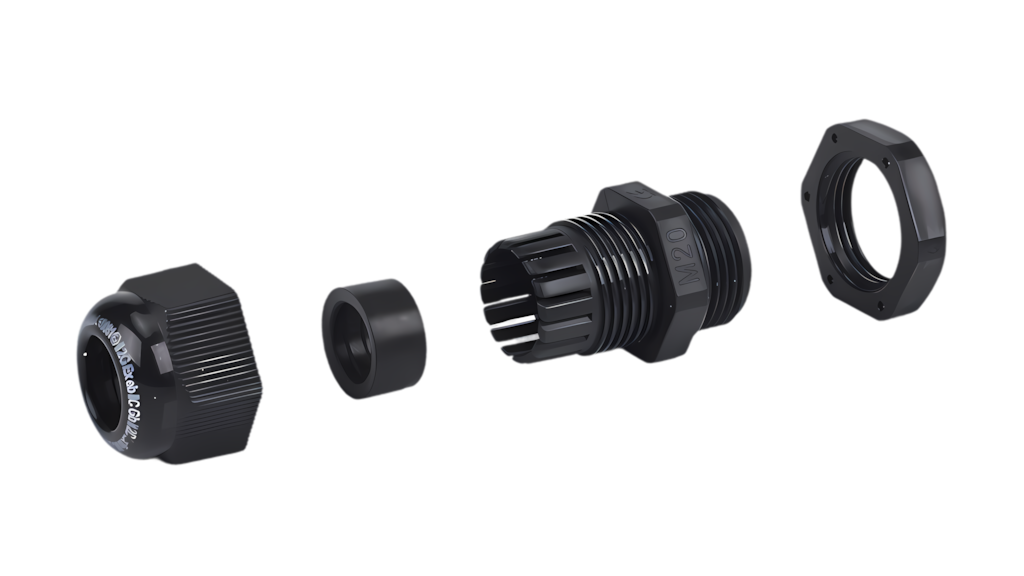

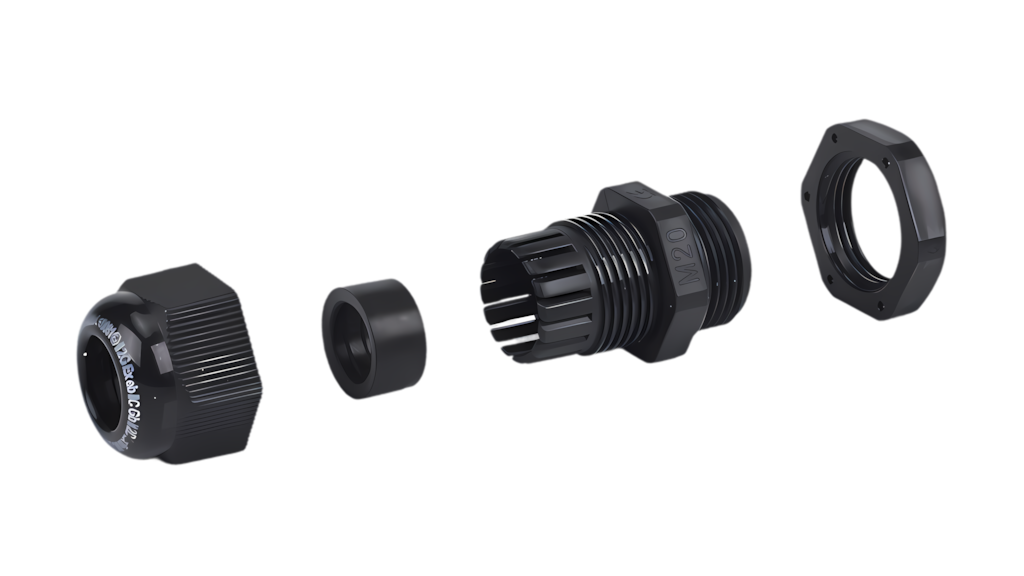

Design and Construction

- Crafted from premium – grade materials, the cable gland offers unparalleled durability and explosion – resistance. Stainless steel variants provide exceptional corrosion resistance, making them suitable for harsh marine or chemically – aggressive settings, while flame – retardant alloy options combine strength with fire – prevention properties. The gland’s thick – walled structure and precision – engineered components are designed to withstand high internal pressures generated during an explosion, containing the blast and preventing it from propagating to the surrounding environment.

- The sealing mechanism is a key feature of this cable gland. Utilizing high – quality elastomeric seals, it creates an air – tight and watertight barrier around the cable, effectively preventing the ingress of explosive substances. These seals are designed to maintain their integrity over a wide range of temperatures and mechanical stresses, ensuring long – term protection even in extreme conditions. The gland’s threaded connections are also meticulously designed, with precise thread profiles that guarantee a secure, gas – tight fit when attached to equipment or conduits.

ATEX Compliance and Certification

- ATEX certification is not just a label; it’s a testament to the gland’s compliance with Directive 2014/34/EU, which covers equipment and protective systems intended for use in potentially explosive atmospheres. This cable gland has been tested and approved for use in various hazardous zones:

- Zone 0: Areas where explosive gas mixtures are present continuously or for long periods. The gland’s design ensures that it will not generate any sparks or heat capable of igniting these mixtures.

- Zone 1: Areas where explosive gas mixtures are likely to occur during normal operation. Its explosion – proof construction provides a reliable barrier against potential ignition sources.

- Zone 2: Areas where explosive gas mixtures are unlikely to occur during normal operation but may occur occasionally. The gland’s robust sealing and mechanical strength make it a safe choice even in these less – frequent but still high – risk scenarios.

- The certification process involves comprehensive testing of the gland’s electrical, mechanical, and thermal properties. This includes assessments of its ability to withstand impact, vibration, and temperature fluctuations, as well as its electrical insulation and grounding capabilities. By choosing our ATEX certified cable gland, customers can be confident that they are using equipment that meets the highest standards of safety and performance.

Versatile Applications

- This ATEX certified explosion – proof cable gland is an essential component in a wide range of industries. In the oil and gas sector, it is used in refineries, offshore platforms, and pipelines to protect electrical cables from the highly flammable hydrocarbons present. In chemical manufacturing plants, where explosive vapors and dust are common by – products of production processes, the gland ensures the safe operation of electrical systems. Additionally, it finds applications in the pharmaceutical, food processing, and mining industries, where the presence of combustible substances or dust particles requires strict explosion – prevention measures.

In summary, our ATEX certified explosion – proof cable gland offers peace of mind to engineers, operators, and safety professionals. It combines advanced design, high – quality materials, and strict compliance with ATEX standards to provide a reliable and safe solution for electrical connections in even the most hazardous environments.